Sustainable Architecture in Greece with Cross-Laminated Timber (CLT)

At CLT Greece, we see Cross-Laminated Timber (CLT) not just as a modern structural material, but as an architectural philosophy that is redefining how buildings are designed and built in Greece.

Our CLT services combine deep timber engineering know-how, technical precision and sustainability, delivering an end-to-end process – from early concept and feasibility study to the installation of the Mass Timber shell on site.

- Design & preliminary structural assessment for CLT / Mass Timber buildings.

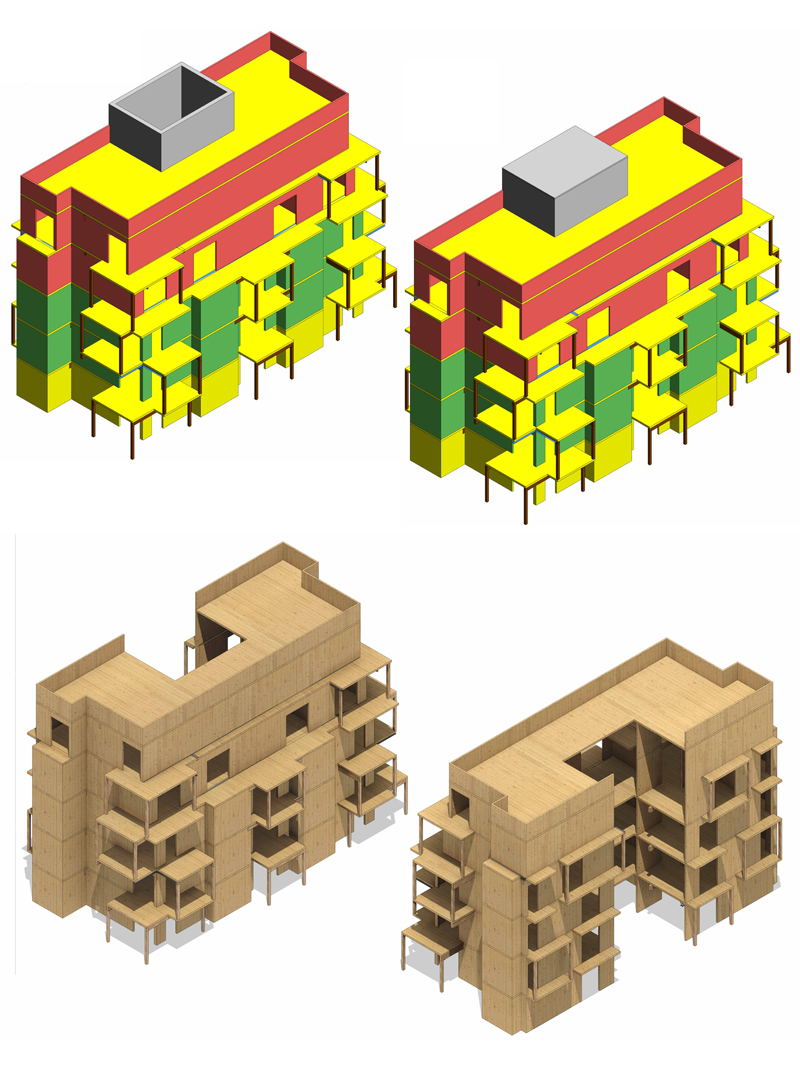

- Cost analysis, detailed technical offer & 3D visualisation of the CLT structure.

- XLAM Dolomiti production, logistics coordination and certified installation.

What We Do

Step-by-Step CLT Project Process

1

CLT Costing, Quantity Take-Offs & 3D Visualisations

From preliminary study to the final technical offer.

➜

The process starts with a preliminary structural assessment that defines the cross-sections and panel thicknesses of the CLT elements. Based on this, we prepare a detailed technical offer that includes all essential components of the Mass Timber structure.

- CLT panels for walls, floors, roofs and stairs (Standard or Visible quality).

- High-precision CNC processing, openings for windows & doors and special cuts.

- Connection and anchoring systems, waterproofing & acoustic membranes.

- Thermal insulation materials & external insulation solutions according to energy requirements.

- Installation accessories (lifting straps and other site equipment).

The final offer is updated after the completion of the structural design, ensuring both technical reliability and accurate project costing.

2

Structural Design for CLT & Mass Timber

The structural core of every CLT project.

➜

The final structural design is the backbone of every CLT building. In collaboration with specialised structural engineers, we prepare:

- Structural calculations for CLT, Glulam or hybrid structural systems.

- Panel and connection dimensioning according to Eurocode 5 and national codes.

- Seismic and wind load checks in line with local technical requirements.

- Integrated analysis of CLT superstructure, foundations and roof for continuity and overall stability.

The result is a documented, safe and efficient CLT structure, ready for production and installation.

3

Technical Manuals & Application Drawings

The complete implementation package for your project.

➜

Every project is supported by a complete technical application file, ensuring accuracy, consistency and safety during erection on site.

- Shop Drawings – detailed drawings per panel and connection point, ready for CNC production.

- Installation Manual – step-by-step erection guidelines for the site crews.

- Membranes & Insulation – guidelines for placing membranes, waterproofing layers and thermal insulation.

- Connection Manual – anchoring tables, tightening torques & fastener types for CLT and timber structures. All connections are based exclusively on Rothoblaas systems, the leading internationally specialized manufacturer of connection solutions for timber and CLT constructions.

4

Production of CLT Panels – XLAM Dolomiti

European production with full certifications.

➜

The CLT panels are produced exclusively in Italy, at the facilities of XLAM Dolomiti, one of the leading European manufacturers of Cross-Laminated Timber.

- EN 16351 certified CLT and complete technical documentation.

- EPD & PEFC certifications for sustainable forestry and full traceability.

- Quality control at every stage: drying, gluing, pressing and CNC cutting.

- Surface options: Standard, Visible or Industrial finish.

- Full compatibility with shop drawings & the final structural design.

5

Transport, Logistics & Site Coordination

Planning of loads, deliveries and site teams.

➜

CLT Greece manages the complete logistics and delivery of the CLT panels to site, ensuring accuracy and speed throughout the erection phase.

- Optimised loading sequence so that panels are installed directly without downtime.

- Planning of site signage and unloading / crane zones.

- Coordination of erection crews and detailed erection schedule.

Our goal is to minimise delays and maximise the efficiency of crane time and on-site teams for your CLT project.

6

Installation of CLT & Mass Timber Shell

Fast erection with certified CLT crews.

➜

Erection is carried out by certified CLT Greece installation crews, under the technical supervision of our engineering team.

- Installation of CLT wall, floor, roof and stair panels.

- Application of connections, anchors & metal components according to the manuals.

- Placement of membranes, sealing tapes and thermal insulation materials.

- Application of external thermal insulation where required, in combination with the timber roof.

- Alignment and quality checks at every stage, based on the shop drawings.

The timber roof and the external thermal insulation can be installed in parallel with the main structure, significantly reducing the overall construction time of the building.

7

Quality Control

Continuous inspection and documentation of the project.

➜

At every stage of installation, quality checks are carried out by the CLT Greece team, in line with the technical specifications and guidelines of XLAM Dolomiti.

- Verification of panel dimensions and positions against the design drawings.

- Inspection of connections, anchors and critical waterproofing details.

- Documentation with photographic and technical records for the project file.

Systematic quality control ensures that the Mass Timber shell performs exactly as designed – structurally, energetically and in everyday use.

Would you like to discuss your CLT project?

- Explore our CLT panel solutions and real Mass Timber projects in Greece: CLT projects & panels in Greece

- Experience CLT construction on real building sites through timelapse videos: CLT project timelapse videos

- Request a tailored CLT project assessment – with no obligation: CLT project assessment

Ready to talk about your next CLT building in Greece?

Email us at

[email protected]

or call

+30 694 248 9034.